While competitions like ROBO-ONE and RoboCup give athletic robots the opportunity to show off their fighting and soccer skills, there are no major competitions that celebrate the robot's ability to make people laugh -- until now, that is. Baka RoboCup (baka means "foolish" or "stupid" in Japanese), a competition organized by entertainment giant Yoshimoto Kogyo, which is arguably Japan's most influential comedy production company, will pit humorous robots against each other in a comedy throw-down this November. Organizers hope the contest will inspire roboticists to devote serious attention to the art of creating impractical (but entertaining) machines.

While competitions like ROBO-ONE and RoboCup give athletic robots the opportunity to show off their fighting and soccer skills, there are no major competitions that celebrate the robot's ability to make people laugh -- until now, that is. Baka RoboCup (baka means "foolish" or "stupid" in Japanese), a competition organized by entertainment giant Yoshimoto Kogyo, which is arguably Japan's most influential comedy production company, will pit humorous robots against each other in a comedy throw-down this November. Organizers hope the contest will inspire roboticists to devote serious attention to the art of creating impractical (but entertaining) machines.

After the October 5 application deadline, the producers will select the 8 most farcical robots and invite them to perform November 4 at Lumine the Yoshimoto in Shinjuku (Tokyo). There, each robot will have 2 minutes to entertain the audience and judges, who will include Nobumichi Tosa (president of nonsense instrument manufacturer Maywa Denki), manga artist Kotobuki Shiriagari, movie director Shinji Higuchi, and University of Electro-Communications professor Masahiko Inami. The 500,000 yen ($4,200) Grand Prize will be presented to the robot who draws the biggest laughs.

To qualify for the competition, aspiring baka-robo must satisfy 3 conditions: (1) they must be mechanical in nature (i.e. they must have moving parts), (2) they must serve no useful purpose (i.e. they must be as impractical and worthless as possible), and (3) they must make people laugh (with entertaining action, amusing features, systems that surprise or shock the audience, etc.). The robots also must be shorter than 240 cm (7 ft 10 in) and weigh less than 100 kg (220 lbs), and they are not allowed to use explosives or emit sparks or liquid.

The Baka RoboCup organization does not seem to have any clearly stated long-term objectives like their soccer-oriented RoboCup counterparts -- who aim to produce a team of robots capable of outperforming a team of world champion human players by the year 2050. However, a statement by Nobumichi Tosa on the BacaRobo website suggests one goal is to challenge the notion that robots must be regarded as serious machines that serve a practical purpose. That said, the serious pursuit of creating "frivolous" machines might play a useful role in the development of artificial intelligence, innovative mechanical features or social satire, suggests Tosa.

[Source: BakaRoboCup 2007 Official Site]

Toyota's "DJ Robot," a two-wheeled android belonging to a band of robot musicians that entertained visitors at the 2005 Aichi World Expo, has ditched its entertainment career for a job as a receptionist. DJ Robot's departure from the band comes as Toyota gears up for its debut of a new robot violinist this autumn.

Toyota's "DJ Robot," a two-wheeled android belonging to a band of robot musicians that entertained visitors at the 2005 Aichi World Expo, has ditched its entertainment career for a job as a receptionist. DJ Robot's departure from the band comes as Toyota gears up for its debut of a new robot violinist this autumn.

An autonomous robot janitor built by Subaru (Fuji Heavy Industries) and Sumitomo has landed a job cleaning the outdoor hallways of a new 14-story Bali-themed luxury apartment complex in Tokyo. Lovingly nicknamed 'Tondon' in an apparent reference to a legendary Balinese snake god, the robot is a close relative of

An autonomous robot janitor built by Subaru (Fuji Heavy Industries) and Sumitomo has landed a job cleaning the outdoor hallways of a new 14-story Bali-themed luxury apartment complex in Tokyo. Lovingly nicknamed 'Tondon' in an apparent reference to a legendary Balinese snake god, the robot is a close relative of

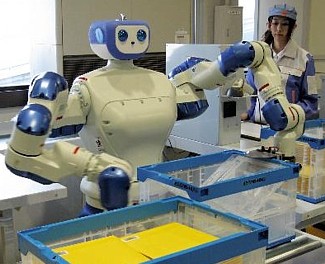

Industrial robot maker Yaskawa Electric has teamed up with megaconglomerate Mitsui & Co., Ltd. and packaging system manufacturer Hokusho Co., Ltd. to develop a parcel sorting system that employs agile robot workers capable of quickly classifying and separating small items such as mail packages and clothing. The system, now being demonstrated at one of Hokusho's factories, employs Yaskawa's Motoman-DIA10, which features a pair of smooth-moving, seven-axis robotic arms mounted on a human-sized torso.

Industrial robot maker Yaskawa Electric has teamed up with megaconglomerate Mitsui & Co., Ltd. and packaging system manufacturer Hokusho Co., Ltd. to develop a parcel sorting system that employs agile robot workers capable of quickly classifying and separating small items such as mail packages and clothing. The system, now being demonstrated at one of Hokusho's factories, employs Yaskawa's Motoman-DIA10, which features a pair of smooth-moving, seven-axis robotic arms mounted on a human-sized torso.